Consultancy

Wavelength NDT's consultancy capability lies with Dr. Richard Freemantle who has over 20 years experience in non destructive testing and ultrasonic science and technology. His unique and comprehensive background in both industrial and research sectors has made him widely sought after as an NDT inspector and technical consultant, particularly in the field of composites. To find out more about Richard and his activities please feel free to contact him through LinkedIn ( ![]() View Richard Freemantle's profile) or through our contact page.

View Richard Freemantle's profile) or through our contact page.

Wavelength NDT can conduct small feasibility and demonstrator projects in any aspect of NDT technology through to large scale R&D projects involving technique development, validation and procedure writing. As an independent contractor, with no ties to a particular product range, we are able to advise on equipment and techniques purely on their merit and suitability to the application. We firmly believe in a strong customer relationship and, if required, R&D projects can be carried out at the client's premises with Wavelength NDT working with your engineers and NDT technicians.

Wavelength NDT have worked on many types of project including:

• Providing second opinions on inspection work and advising clients on how to evaluate the inspection results. This includes helping the client to develop an appropriate acceptance criteria for defects based on stress and design analysis of the structure.

• Demonstrating the capability of NDT methods and developing inspection techniques for the assembly of carbon fibre primary aerospace structures. This includes developing inspection techniques suitable for handheld thickness gauges through to advanced phased array inspection of complex geometries.

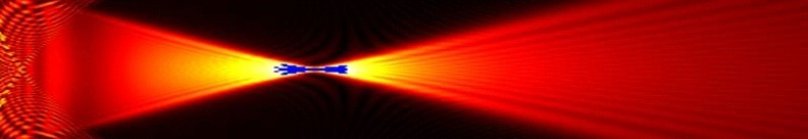

• Developing, validating and preparing an advanced inspection technique for the inspection of fibre waviness in carbon and glass fibre pre-preg laminates. This includes modelling work to predict the sizing capability of the method and optimise the inspection parameters.

• Developing phased array inspection methods for complex shaped composite parts. This includes developing suitable coupling methods which could be easily deployed for production inspection.

• Evaluating the deployment of Full Matrix Capture phased array techniques for the inspection of engineering structures. This includes advising the client on how to prepare suitable calibration and reference specimens in order to validate the technique they had developed.